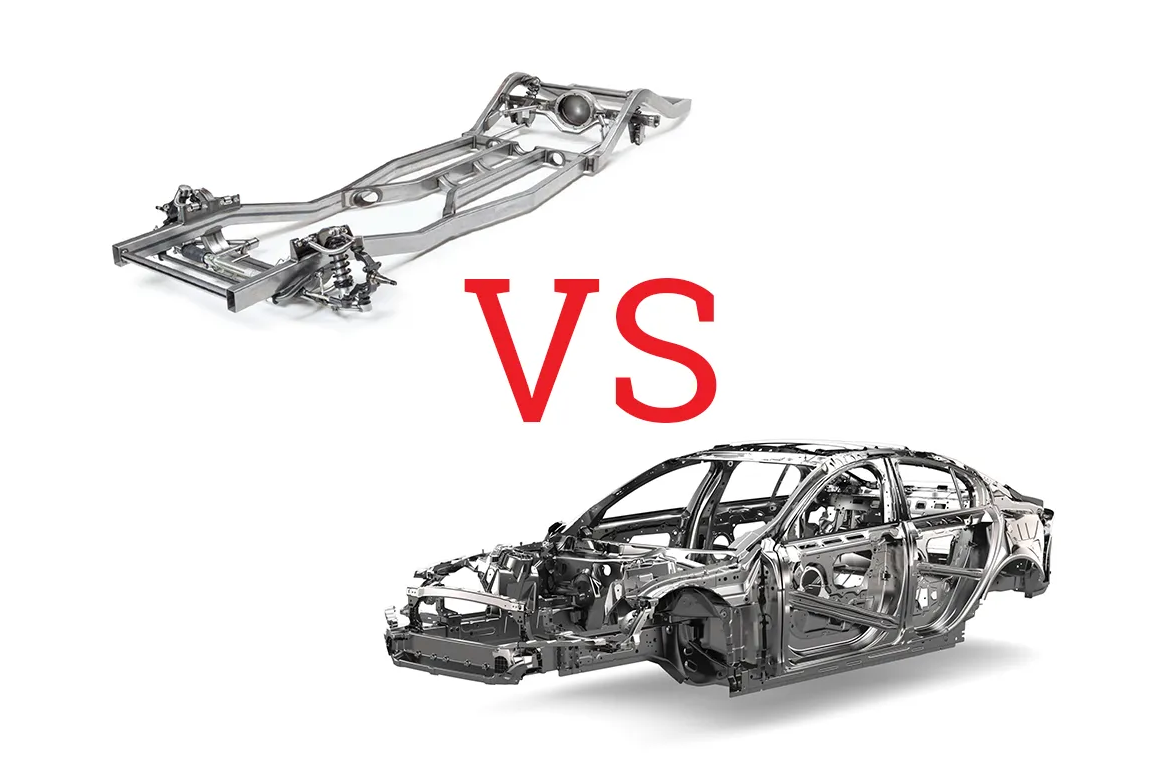

Unibody vs. Body-on-Frame — The “Chassis Battle” in New Energy Vehicles

BYD’s Leopard brand recently launched the second model of its “Titanium” series, the Titanium 7, a large SUV designed with more urban appeal than its rugged siblings. This release has reignited the long-standing debate between Unibody (Monocoque) and Body-on-Frame (Ladder Frame) structures — a debate now entering the new energy vehicle (EV) era.

🏗 Structural Definitions and Principles

🔹 Unibody (Monocoque)

Definition: The body and chassis are integrated into a single structure. The body itself bears and distributes weight and forces, with reinforcement through beams and stiffeners.

Features: Lightweight, highly integrated, efficient use of space, and cost-effective mass production.

🔹 Body-on-Frame (Ladder Frame)

Definition: A separate rigid frame supports the engine, drivetrain, and body, while the body acts as a shell mounted on the frame.

Features: Strong, durable, impact-resistant, and repair-friendly. Best suited for heavy-duty use and off-road conditions, but comes with added weight.

⚖ Pros and Cons at a Glance

| Aspect | Unibody | Body-on-Frame |

|---|---|---|

| Weight & Energy Use | Lighter, lower consumption, better range | Heavier, higher energy consumption |

| Rigidity & NVH | High torsional rigidity, better NVH performance | Strong frame absorbs shock, but body joints may create noise |

| Space Efficiency | Maximized interior space, flexible layouts | Frame takes space, reducing ground clearance |

| Manufacturing & Cost | Efficient for large-scale production | Simpler design but requires separate frame + body manufacturing |

| Durability in Extreme Use | Can deform under heavy load/off-road | High strength, reliable under harsh conditions |

| Repair & Modification | Complex repairs, requires precision | Flexible for repairs and modifications |

| EV Relevance | Battery can integrate into chassis (skateboard platform) | Rare in EVs, but useful for electric pickups and commercial vehicles |

🚗 Applications in New Energy Vehicles

🔹 Unibody EV Examples

BYD Seagull

A compact city EV with a curb weight of ~1160 kg, blade battery, and range of 305–405 km. The unibody design ensures lightweight efficiency, affordability, and urban adaptability.Tesla Model Y (with giga-casting)

Large rear underbody castings replace hundreds of parts, boosting rigidity and manufacturing efficiency. A benchmark for unibody EV innovation.

👉 Takeaway: Unibody structures dominate passenger EVs due to their efficiency, scalability, and lightweight advantage.

🔹 Body-on-Frame EV / Hybrid Examples

Mercedes-Benz EQG (Electric G-Class)

Maintains the traditional ladder-frame architecture, optimized for off-road performance with strong battery protection, water-fording, and high ground clearance.Traditional Rugged SUVs (fuel examples but relevant blueprints): Jeep Wrangler, Toyota Land Cruiser, Nissan Patrol, Mitsubishi Pajero, Beijing BJ40, Haval H9, etc.

All use body-on-frame designs, serving as reference points for future electric off-roaders.

👉 Reality Check: Pure EVs with ladder-frame designs are still rare in passenger markets. Their main presence remains in pickups, commercial vehicles, and hardcore off-roaders.

🔮 Future Trends and Technical Outlook

⚡ Hybrid “Skateboard + Unibody” Platforms

Rivian R1S, Jaguar I-Pace, and VW ID series showcase integrated battery packs acting as structural components, balancing lightweight unibody benefits with added rigidity.

⚙ Giga-Casting Innovations

Tesla’s casting breakthroughs reduce weight and cost while increasing rigidity, setting new benchmarks for EV unibody structures.

🚛 Body-on-Frame EV Platforms

Electric pickups and heavy-duty trucks show market potential. Their modular “frame + electric powertrain” setups combine durability with EV adaptability.

🧪 Lightweight Materials

Future EVs will increasingly rely on aluminum alloys, composites, and high-strength steel to achieve rigidity, lower weight, and extended driving range.

✅ Conclusion

The Unibody vs. Body-on-Frame debate in EVs reflects two different philosophies:

Unibody: Lightweight, efficient, space-maximizing — the mainstream choice for passenger EVs.

Body-on-Frame: Rugged, durable, modification-friendly — the go-to for off-road, commercial, and specialty vehicles.

In the EV era, Unibody remains dominant, but Body-on-Frame holds steady in niches like off-roading and heavy-duty applications. The right choice depends on your driving needs, market positioning, and long-term goals.

Please explore our blog for the latest news and offers from the EV market.