Popular Science on New Energy Electric Vehicles: Pros and Cons of NCM and LFP Batteries – Which Should You Choose?

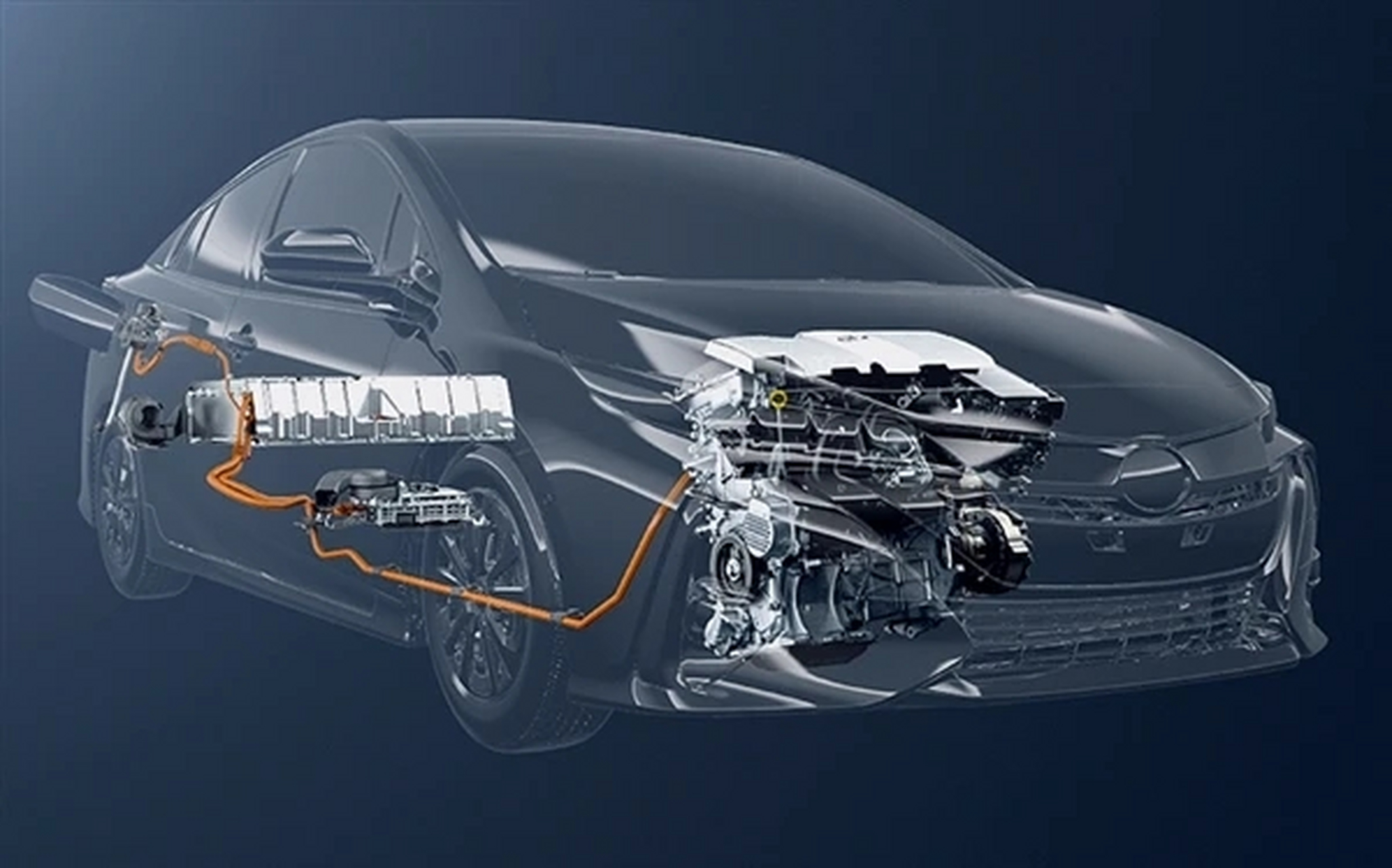

With the gradual development of new energy vehicles, power batteries have also made significant progress, evolving into two major types: Lithium Iron Phosphate (LFP) batteries and Nickel Cobalt Manganese (NCM) batteries.The power battery, as the heart and sole energy source of new energy vehicles, is the most critical system in the entire vehicle, accounting for 30%-40% of the total cost. As consumers, how should we evaluate these two battery types when choosing a car? Let’s dive in.

NCM Batteries

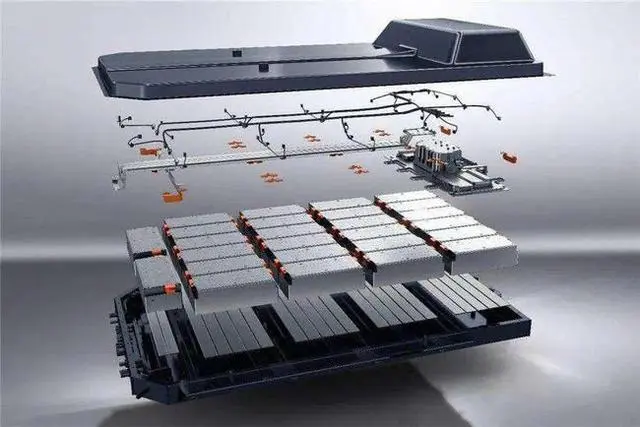

NCM batteries, also known as ternary polymer lithium-ion batteries, use lithium nickel cobalt manganese oxide (Li(NiCoMn)O₂) or lithium nickel cobalt aluminum oxide as cathode materials.

The cathode material of NCM batteries is a composite of nickel, cobalt, and manganese salts, whose proportions can be adjusted as needed. The anode material is typically graphite.

The widespread adoption of NCM batteries by automakers indicates their superior performance compared to other batteries. As an energy storage device combining high energy density and high voltage, NCM batteries utilize the synergy of three materials in a tri-phase eutectic system, making their overall performance better than any single-component compound.

- High Energy Density

Due to the use of more reactive metal elements, mainstream NCM batteries typically have an energy density of 140-160 Wh/kg. High-nickel NCM batteries achieve 160-180 Wh/kg, and some models even reach 180-240 Wh/kg. - High Charging and Discharging Efficiency

When paired with quality charging equipment, NCM batteries achieve an efficiency of approximately 95%. The inherent charging efficiency of the battery itself is around 99.5%. Considering energy loss during discharge, the total charging-discharging efficiency is around 90%. - Good Low-Temperature Performance

NCM batteries can maintain a high capacity and power output even in low-temperature environments, with minimal performance degradation. At -20°C, they retain about 80% of their normal capacity.

However, NCM batteries have notable disadvantages:

Safety Risks

Lithium-ion batteries are prone to thermal runaway at 250-300°C, leading to decomposition. Causes include overcharging, fast charging-induced lithium deposition on the anode causing short circuits, and rapid electrolyte combustion due to overheating.Short Lifecycle

While the theoretical life of an NCM battery is 2,000 cycles, its capacity typically drops to 60% after 1,000 cycles. Even industry leaders like Tesla achieve only 70% capacity retention after 3,000 cycles.

LFP Batteries

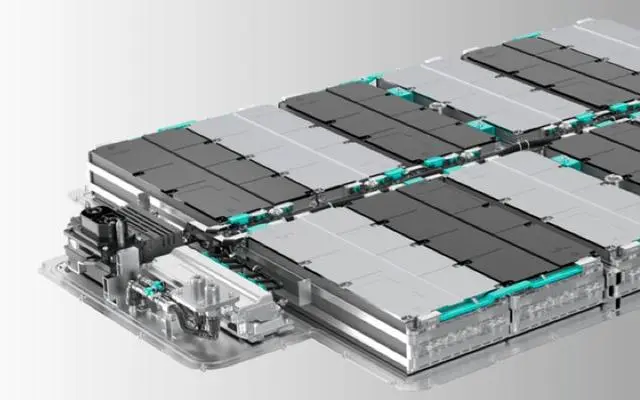

LFP batteries use lithium iron phosphate (LiFePO₄) as the cathode material and carbon as the anode material.

Excellent Thermal Stability and Safety

LFP batteries are the most thermally stable and safest, with a thermal runaway temperature exceeding 500°C, significantly reducing the risk of spontaneous combustion.Stable Electrochemical Performance

The cathode material remains structurally stable during charge and discharge cycles, minimizing risks of combustion or explosion. Even under extreme conditions like short circuits, overcharging, compression, or puncturing, LFP batteries maintain safety.Long Lifecycle

LFP batteries begin to show degradation only after over 3,500 charge and discharge cycles, equating to a service life of over 10 years.Cost Advantages

LFP batteries are also significantly more affordable compared to NCM batteries.

However, LFP batteries have their trade-offs:

Lower Energy Density

The typical energy density of LFP batteries is around 110 Wh/kg. Even BYD’s innovative blade battery achieves only 140-150 Wh/kg, which is the lowest level among mainstream NCM batteries.Lower Charging Efficiency

LFP batteries have a charging efficiency of around 80%, noticeably lower than the 90% efficiency of NCM batteries.Poor Low-Temperature Performance

LFP batteries suffer capacity loss and increased internal resistance in low-temperature environments. At -20°C, they retain only 50%-60% of their normal capacity.

Conclusion

In the passenger car market, the installation rate of LFP batteries surpasses that of NCM batteries. However, NCM batteries, with their higher energy density, are more favored in high-end electric vehicles.

Looking ahead, these two battery types will continue to write their respective histories in their specialized domains.