Is Heating a Major Challenge for Electric Vehicles in Winter?

In the era of internal combustion engine (ICE) vehicles, heating in winter was almost taken for granted: the engine generates a lot of waste heat while running, which the cooling system channels into the cabin to warm the driver and passengers. In other words, heating in ICE vehicles is largely a “byproduct” process, and its impact on fuel economy is relatively minor.

But for all-electric vehicles (BEVs / EVs), the situation is completely different: they must actively consume electrical energy to generate heat. That makes cabin heating one of the most sensitive “energy killers” in cold-weather electric driving. If not managed well, the energy used for heating can reduce range by 10%–30%, and under extreme conditions, even more.

As winter approaches in the Northern Hemisphere, this heating issue is increasingly a concern for new energy vehicle owners. Below we start from the principles and gradually dive deeper.

🔧 Heating System Principles & Energy Mechanisms

1. Two Main Heating Technology Paths: Resistive (PTC) vs Heat Pump

Currently, the in-cabin heating systems in electric vehicles follow two main technical routes:

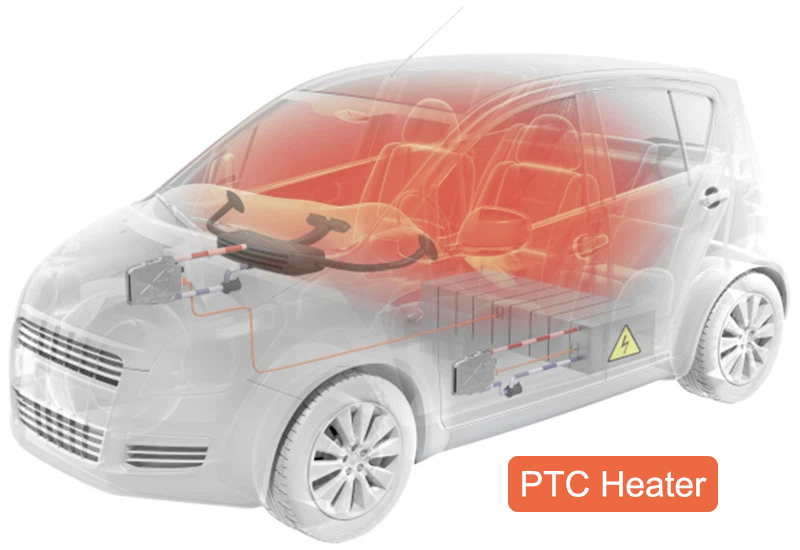

1.1 Resistive Heater / PTC Heater

PTC (Positive Temperature Coefficient) heaters are resistive heating elements whose resistance increases as temperature rises, giving them some degree of self-limiting behavior.

Their operation is akin to an “electric heater”: they convert electrical energy directly into heat, which is then delivered via airflow to warm the cabin.

In theory, the efficiency of resistive heating (heat output ÷ input electrical energy) can be assumed to be 100% (i.e. COP = 1), because there’s no “heat transfer” process—ultimately all the electrical input becomes heat.

However, this method runs into a serious problem: in cold winter conditions, a large heating power is required, drawing substantial power from the battery and severely affecting driving range.

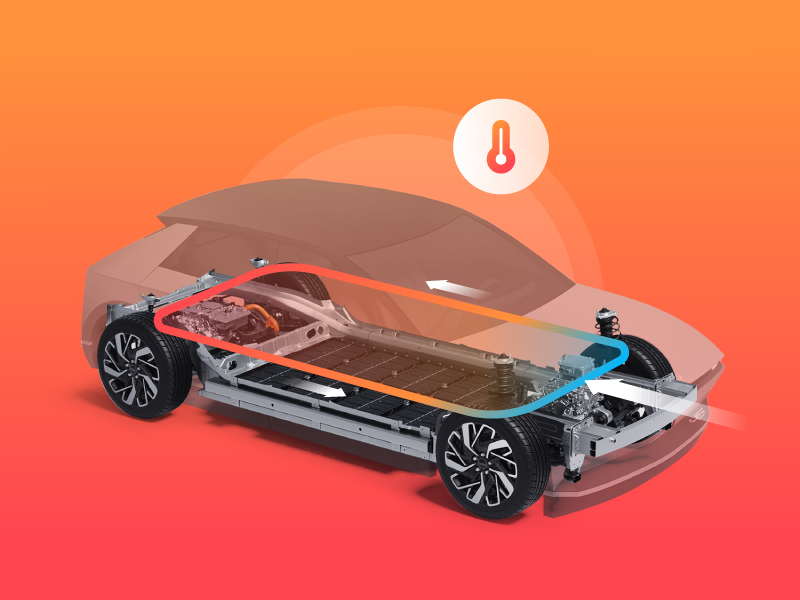

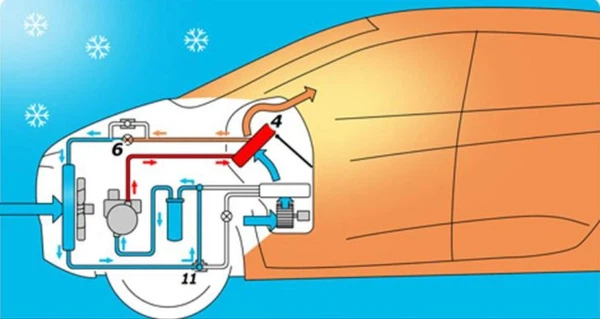

1.2 Heat Pump Heating System

A heat pump works by moving heat rather than making heat: it absorbs heat from an external source (such as ambient air, refrigerant, or waste heat) and uses compressors, expansion valves, etc., to transfer that heat into the cabin or to battery/other components.

The performance of a heat pump is commonly expressed by COP (Coefficient of Performance) = “heat moved” ÷ “electrical input.” A COP = 3 means 1 unit of electrical energy can transport 3 units of heat into the cabin.

In mild cold environments (e.g. around 0°C to 10°C), a heat pump can often achieve COP = 3–4, which is why it is more energy efficient than PTC heating. Many studies and real-world tests indicate that heat pumps during winter heating can save 30%–50% of energy consumption compared to PTC systems.

However, heat pumps also have limitations: in extremely cold environments (e.g. far below 0°C, or –20°C and lower), the efficiency (COP) of heat pumps drops sharply, and they may have to rely on resistive heating as an auxiliary. Moreover, heat pump systems are more complex, more costly, and demand higher standards in design, sealing, and reliability of heating/cooling components.

Hence, many automakers today adopt a hybrid model of “heat pump + resistive heating” in mid- to high-end vehicles, aiming to strike a balance between heating efficiency and cost across different temperature ranges.

2. Energy Consumption Components & Range Impact Mechanism

To understand how winter cabin heating affects EV range, one must be aware of several sources of energy consumption:

Heating system’s own power draw: Whether using PTC or heat pumps, supplying heat to the cabin draws power from the high-voltage battery. This could reach magnitudes of 1.8 to 4 kW, depending on temperature differential, cabin volume, insulation, etc.

Battery & thermal management system consumption: In cold environments, the battery’s chemical reaction activity decreases, internal resistance rises, and both capacity and output efficiency degrade. To maintain the battery within an optimal temperature range (e.g. 15–25°C), vehicles often need to preheat or thermally regulate the battery, which also consumes energy.

Reduced driving efficiency & increased resistance: Cold weather tends to increase air density, tire rolling resistance, friction coefficients, etc., resulting in higher energy consumption per distance traveled. Additionally, the motor, inverter, and other drive components may suffer slight efficiency drops at extremely low temperatures.

In real-world driving conditions, winter range loss tends to be a combination of the heating system’s power draw plus elevated energy use from reduced battery performance and lower driving efficiency. Based on many real-world and simulated data, EVs in frigid weather (e.g. below 0°C) may lose around 20%–50% of their driving range.

Therefore, properly designed and intelligently used heating systems in winter are key to making electric vehicles competitive in cold climates.

🛠️ User Strategies & Suggestions for Reasonable Use of Heating in Winter

While hardware design is foundational, for end users, the correct and reasonable use of the heating system is what really mitigates range loss and improves winter driving comfort.

1. Preheat Before Departing (Pre-conditioning)

If your vehicle supports “scheduled preheat” or “preheat while charging,” it’s advisable to start warming the cabin and battery while still plugged in. That way, the first segment of your drive starts at a higher initial temperature, reducing the energy shock required for temperature rise.

For vehicles without a preheating feature, you might run the HVAC (heating system) for a few minutes while stationary before starting your trip, if conditions allow, to raise cabin and battery temperatures.

The benefit: in the first part of the trip, heating demands are lower, and competition for energy between drivetrain and heating is reduced, which leads to more stable range performance.

2. Use Low-power Heating Means First

In the initial phase, don’t try to rapidly boost cabin temperature to a very high level. Instead, rely on local heating like seat warmers or steering wheel heaters to allow the driver to feel warm quickly. This helps avoid the heating system blowing at high power and consuming large energy bursts.

When traveling at higher speed or under high power consumption conditions, you can lower the blower temperature setting or even close some recirculation vents to protect range.

3. Set a Moderate Cabin Temperature

Set the cabin temperature to a reasonable, comfortable level (e.g. 20°C–23°C), avoiding aggressive setpoints (like 25°C–28°C) that cause excessive heating and unnecessary energy consumption.

In extremely cold conditions, avoid frequent high/low temperature toggling or sudden jumps, which may cause the system to frequently adjust or switch modes and lead to lower efficiency.

4. Use “Eco / Energy-Saving” Heating Modes Wisely

If your vehicle has an “economy heating” or “Eco heat” mode, favor it during everyday driving. Switch to “comfort heating” only when strong warming is truly needed.

In economy mode, blower speed, heating ramp rate, or output power may be limited, but for most daily use, it should suffice.

5. Parking Location & Insulation

If possible, park in a garage or sheltered area to avoid prolonged exposure to extreme cold. That way, the energy needed for preheating will be much lower.

If indoor parking is not available, try to prevent the car’s exterior from freezing or frosting, which reduces extra energy loss from window defrosting or cabin heating when first starting.

6. Driving Style & Speed Control

In extreme cold, drive smoothly, avoid sudden acceleration or high speeds, which reduces the intrinsic energy cost of driving and allows the relative share of heating consumption to be smaller.

Where conditions allow (e.g. highways, long trips), consider turning off nonessential high-power accessories (e.g. powerful audio systems, extra heaters, etc.) to save energy.

🔍 Future Trends & Innovation Directions

Solid / Semi-solid State Batteries & Thermal Management

Next-gen solid or semi-solid batteries may have better thermal tolerance and stability, potentially reducing or optimizing battery preheating energy needs. This could provide more flexibility in vehicle thermal management systems.

More Efficient Heat Pumps & Next-Gen Refrigerants

By adopting higher-performance refrigerants, compressors with better low-temperature performance, and optimized heat exchanger designs, it will be possible to extend the efficient operating range of heat pumps under extreme cold.

Heat Recovery & Waste-heat Coupling Design

Better integrating waste heat from motors, inverters, cooling systems, and vehicle electronics into the cabin heating and battery thermal management systems can create an overall thermal loop, improving system efficiency.

Intelligent Thermal Management & OTA Optimization

Utilizing cloud data, AI models, and OTA software upgrades, the vehicle’s HVAC control logic can continuously evolve and optimize, achieving more precise balancing of energy consumption and comfort.

Auxiliary Heating Technologies

In extreme cold environments (e.g. far northern regions, mountainous areas), supplementary heating methods may be explored: small methanol heaters, micro heat sources (e.g. micro organic Rankine cycles), infrared heating panels, or even fuel cell–based heating systems.

Including Low-Temperature Conditions in Winter WLTP / Standardized Tests

As EV adoption expands to colder regions, more jurisdictions may demand standardized testing include low-temperature conditions to better reflect winter range performance for consumers. This would push automakers to upgrade their heating and thermal control systems.

🏁 Conclusion

Technological evolution takes time. Perhaps in the not-so-distant future—with mass production of semi-solid/solid-state batteries, further optimization and cost reduction of heat pump systems—EV owners will no longer need to agonize over choosing “temperature or range” during winter. But until then, understanding how your vehicle’s heating system works, and applying energy-saving techniques, may help you drive more confidently and comfortably through cold days.

Please explore our blog for the latest news and offers from the EV market.