Why Do EV Batteries Seem to Lose Their Stamina in Winter?

With the rise of new energy vehicles, many owners face the same winter dilemma — their range drops significantly and charging becomes less efficient. What you might easily cover in summer suddenly demands frequent “refuel” planning when winter hits. Why does temperature and season impact the battery’s “range power” so drastically? What deeper effects is cold having on the battery?

Catalog

Core reason: Ion transport & electrochemical kinetics slow down in cold

Lithium-ion batteries rely on rapid migration of lithium ions between the positive/negative electrodes and the electrolyte, plus intercalation/de-intercalation reactions at the electrode surfaces. Cold affects these processes primarily in two ways:

Electrolyte viscosity increase / ion conductivity decrease – When temperature drops, the electrolyte becomes more viscous, lithium‐ion migration slows and overall ionic conductivity falls, which limits internal mass transport and weakens current output.

Electrode/interface kinetics slow down – The rate of charge transfer reactions at the electrode surface decreases markedly with lower temperatures (due to activation energy effects), which reduces usable power and transient response; in simple terms, the battery isn’t delivering because it can’t “move” ions fast enough in the short term.

These fundamental electrochemical effects are the first-principle reasons low temperature leads to reduced range and diminished acceleration.

Interface issues: SEI, lithium plating & irreversible damage

On the negative electrode (typically graphite) there is a solid electrolyte interphase (SEI) film. Under normal temperatures it remains stable, but in cold conditions two risks emerge:

Lithium metal deposition (lithium plating) during charging – When the battery is cold and the graphite anode cannot timely absorb intercalating lithium ions, excess lithium ions may deposit on the anode surface as metallic lithium, forming lithium plating. This not only consumes reversible lithium ions and reduces capacity, but also increases internal resistance and may provoke piercing short-circuit safety risks. That’s why many battery management systems (BMS) limit charging power or even forbid fast-charging under low temperatures to prevent lithium plating.

SEI behaviour under low temperature – Cold makes some components in the SEI less conductive, raising interface impedance and hindering charge transfer.

Thus, inappropriate charging in winter (especially high-current fast charging) may lead to irreversible capacity loss — one reason behind the worry “battery is more likely to go bad in winter”.

Internal resistance rises → more energy turned into heat → less driving energy usable

Under cold conditions the battery’s equivalent internal resistance (including ohmic, interface, diffusion resistances) increases. On discharge, voltage drops across the internal resistance and increased heat losses cause:

For the same nominal energy, less actual energy is delivered to the motor (less energy used for torque), so range decreases.

Under heavy loads (acceleration, climbing, low state-of-charge regeneration) the voltage drop becomes more pronounced, the vehicle may feel power decline or trigger current-limiting/power-reduction protections.

In short: the battery isn’t “suddenly much smaller in capacity”, but a part of its energy is wasted as heat in the internal resistance, and meanwhile the BMS may proactively reduce power to protect the battery – so you feel worse driving and shorter range.

Whole-vehicle energy consumption increases & system-level impacts

Beyond the battery’s own electrochemical issues, several systemic factors worsen winter range:

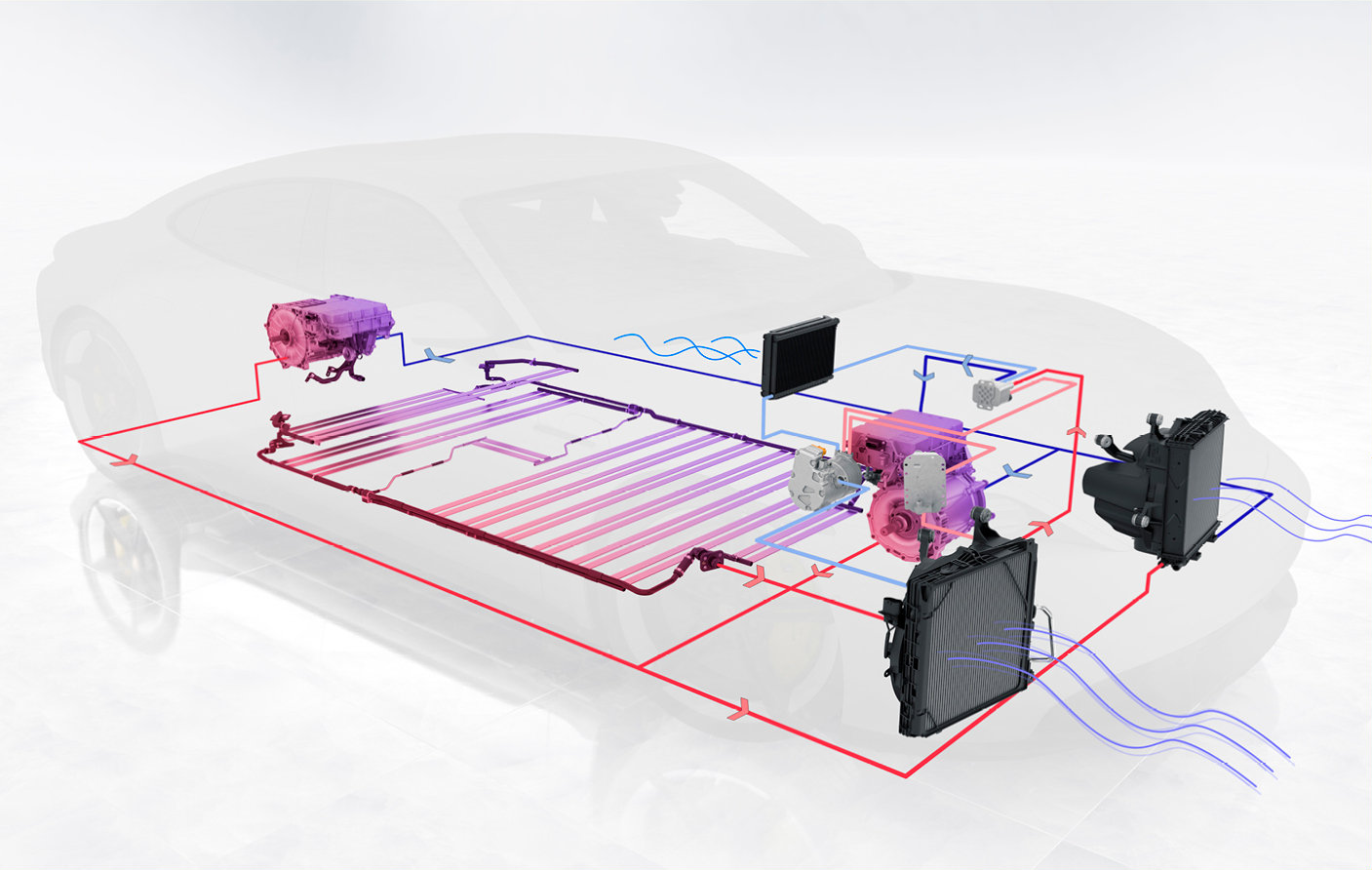

HVAC (heating/ventilation/air-conditioning) consumption is large – Pure electric vehicles lack engine waste-heat; heating either uses high-power resistive heaters (inefficient) or heat pumps (more efficient but limited in extreme cold). Studies show using traditional resistive heating can lead to range drop of 30–40% in some conditions, whereas vehicles with heat pumps suffer significantly less (typically around 10% drop, depending on model/conditions).

Regenerative braking is limited – When battery temperature is low or state-of-charge (SOC) is high, the BMS may restrict battery charge/discharge power, reducing regen braking or disabling it altogether. That leads to lost recovery energy, further reducing effective range.

Tire pressure, air-drag & driving conditions change – Cold reduces tire pressure, increasing rolling resistance; icy/wet roads prompt more frequent stop/starts or accelerations, increasing energy consumption.

Collectively, winter range loss is the result of “battery chemistry + whole-vehicle energy demands + protective strategies” layered together.

What manufacturers & researchers are doing (tech directions & counter-strategies)

To improve low-temperature performance, the industry and academia are pursuing major tech tracks:

Electrolyte & additive engineering – Lowering viscosity at low temperature, increasing ionic conductivity, optimizing SEI precursor formation to improve low-temperature ion transport & interface stability. Recent reviews and studies focus heavily in this direction.

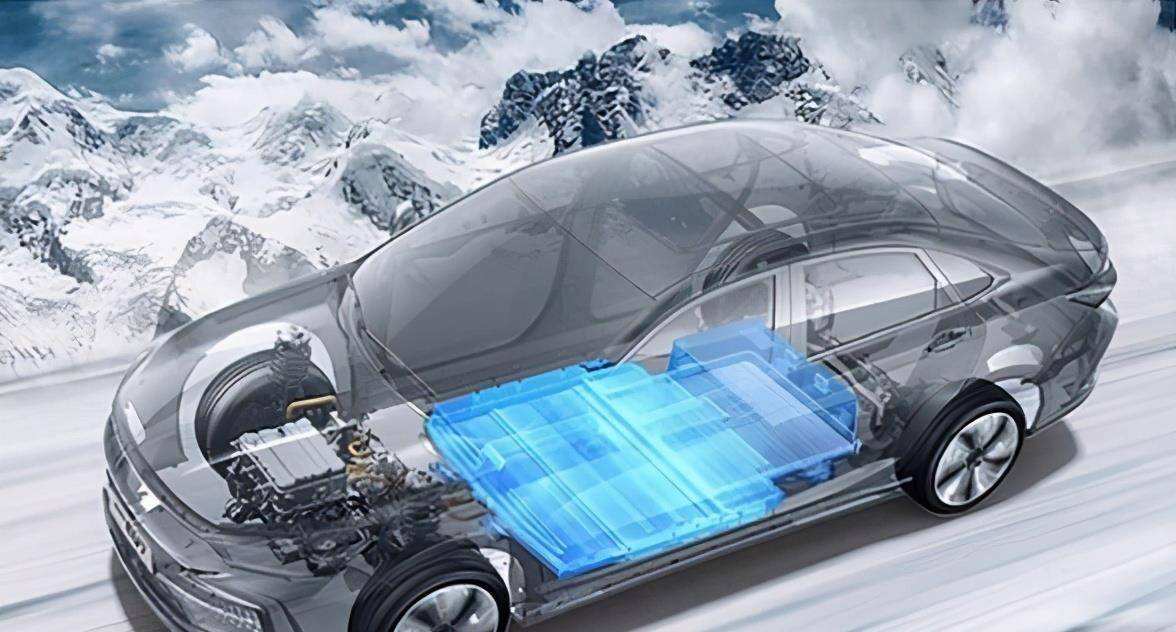

Battery thermal management (BTMS) improvements – Active pre-heating (electric heating bands, liquid-coolant heating loops), integration of heat pumps into vehicle thermal management systems; this enables heating the battery before start or early in driving to the ideal working temperature range, reducing cold-temperature losses.

BMS strategy optimization – Smarter pre-heat and charge/discharge strategies, model-based temperature prediction and zone heating, enabling more flexible regeneration/discharge limits within safe zones to find a better balance between protection and performance.

Practical operations owners can do (reducing winter range loss)

Pre-heat before departure and if possible pre-heat while plugged in: Many models support pre-heating the battery and cabin via app while connected to external power—this saves vehicle energy (uses grid) and gets the battery into a more efficient temperature range, reducing initial internal resistance losses and regen restrictions.

Prefer models with heat-pump or strong thermal-management: When choosing a vehicle, look for heat pump or intelligent thermal management systems—these significantly matter in winter range.

Avoid high‐rate fast charging when battery is extremely cold: Cold fast charging easily leads to lithium plating, causing long-term battery damage. If you must charge, pre-heat the battery first or use low-power slow charging.

Keep correct tire pressure & good tire condition: Cold reduces tire pressure and increases rolling resistance; regularly check tire pressure to cut unnecessary energy loss.

Minimize use of high‐power electrical accessories (seat/steering-wheel heaters are more efficient than full cabin heat): Localized heating (seat, steering wheel, windshield heaters) is more energy-efficient than heating the entire cabin, which can preserve “perceived comfort” while reducing range loss.

✅ Conclusion

Winter range reduction in EVs is a multi-factor natural phenomenon: the core lies in low temperature suppressing ion migration and interface reaction rates inside the battery, raising internal resistance and triggering protective strategies, while the vehicle’s heating and regen systems are also impacted, reducing usable energy further. It is not simply “battery quality is bad”, but rather the inevitable behaviour of materials, physics/chemistry and control decisions under severe cold. By choosing advanced thermal management (such as heat pumps), adopting smart usage habits (pre-heating, avoiding cold fast-charging) and as manufacturers improve electrolyte & BMS technologies, winter performance can be significantly improved. Looking ahead, as material and system engineering progress, EVs’ adaptability in cold climates will continue to improve—bringing users four-seasons driving experiences closer to those of internal-combustion vehicles.

Please explore our blog for the latest news and offers from the EV market.