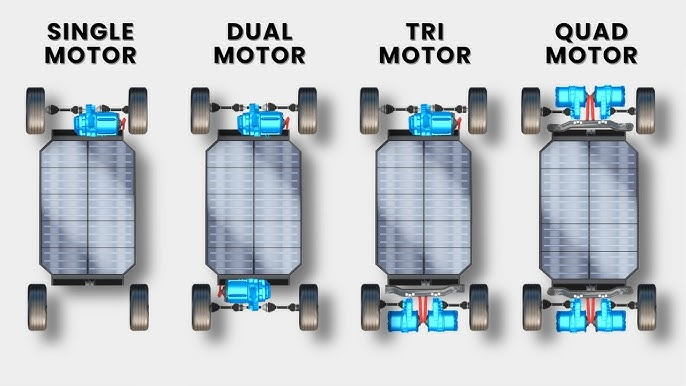

Dual-Motor Drive Technology Explained

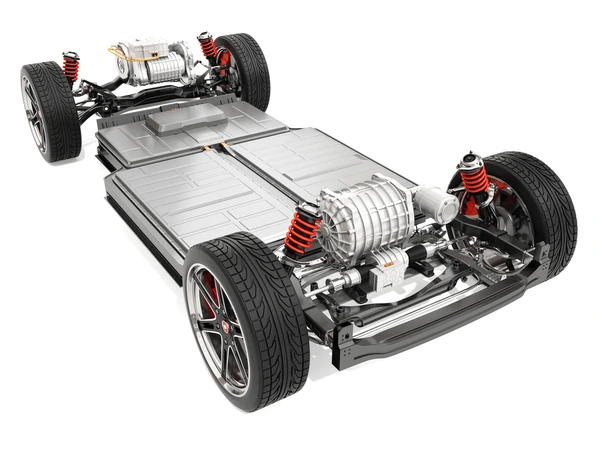

For electric vehicles (EVs), dual-motor systems offer a range of clear advantages over single-motor setups paired with a main reducer or gearbox, especially in terms of improving drive efficiency and performance. By utilizing two motors—typically one on each axle—EVs can distribute power more intelligently, operate each motor in its optimal efficiency range, and adapt seamlessly to varying driving conditions.Let’s break down why.

🔋 Advantage 1: Higher Efficiency Across More Driving Conditions

A single motor’s efficiency drops significantly in low-speed, high-load situations or at high speeds under light loads.

Although EV motors have a much wider high-efficiency range than internal combustion engines, they still face challenges:

Strong acceleration and climbing require high torque.

Speeds from 0 to 100+ km/h demand a wide rotational speed range.

While most medium-to-high-speed conditions yield excellent motor efficiency, low-speed heavy loads or high-speed light loads can see efficiency drop by 20–30% compared to peak values.

With two motors, the system can distribute workloads more effectively, expanding the high-efficiency operating range.

♻ Advantage 2: Improved Regenerative Braking Efficiency

In a dual-motor coupled drive system, there are four possible modes:

Single-motor drive

Dual-motor drive

Single-motor regenerative braking

Dual-motor regenerative braking

Driving efficiency and regenerative efficiency are essentially the same concept—when in “motor” mode it’s driving efficiency, when in “generator” mode it’s recovery efficiency. Two motors offer more opportunities for high-efficiency recovery, improving regenerative braking performance.

🚗 Advantage 3: No Power Interruption

A single motor can be paired with a multi-speed gearbox for better efficiency, but gear changes cause power interruptions. Dual motors with coordinated control eliminate this problem entirely.

⚙ Advantage 4: Reduced Weight & Manufacturing Complexity

Designing one motor for both high torque and high RPM is challenging and results in heavier units. Splitting the load between two motors lowers manufacturing difficulty and total system weight—often by 30% or more—while still exceeding the performance of a single high-power motor.

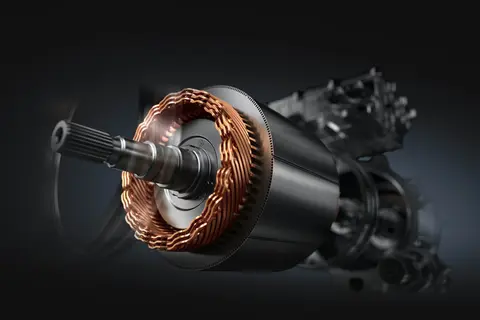

🔧 Types of Motors in Dual-Motor EVs

Most EVs today use Permanent Magnet Synchronous Motors (PMSM) or Induction Motors (IM). A front-and-rear combination yields four possible setups. Below are examples of common configurations.

🌀 Dual Induction Motors (IM + IM)

Mercedes-Benz EQB

Front & rear asynchronous induction motors.

Front motor optimized for efficiency in mid-low speed; rear motor provides performance.

Max output: 215 kW, torque 520 Nm, 0–100 km/h in 6.3s.

Pros: High torque at launch, flexible motor placement, lower cost.

Cons: Higher energy consumption, larger size, lower efficiency in low-speed city driving.

NIO ES8 Founders Edition

Equipped with XPT “3-in-1” dual-motor drive system using both induction and permanent magnet motors.

Front: Induction motor from the XPT 100–300 kW platform, delivering up to 240 kW power, 420 Nm torque, with transmission efficiency over 97% and low drag losses to help extend range.

Rear: Permanent Magnet Synchronous Motor from the XPT 100–200 kW platform, producing 160 kW power and 305 Nm torque, with energy conversion efficiency up to 96.7%.

Modular design allows combination with different motor types and power levels, ideal for AWD layouts.

The pairing of an induction motor at the front for high-speed efficiency and a PMSM at the rear for low-speed torque gives the ES8 strong, stable performance and improved range compared to its previous dual-induction setup.

🛠 Permanent Magnet + Induction (PMSM + IM)

Tesla Model 3 Performance & Model Y

Front: Induction motor; Rear: PMSM.

Takes advantage of IM’s high-speed efficiency and PMSM’s low-speed efficiency.

Coil-winding upgrades (hairpin motor design) improve power density and reduce size.

This combo is widely regarded as the current optimal setup in the industry.

VW ID.4 CROZZ

Same IM front + PMSM rear setup.

Both motors are Volkswagen in-house developed.

🧲 Dual Permanent Magnet Motors (PMSM + PMSM)

BYD Han EV AWD

Front PMSM: 163 kW; Rear PMSM: 200 kW with SiC control.

Blade battery system (76.9 kWh), AWD version adds rear “3-in-1” motor unit.

Modular design and advanced cooling enhance safety.

XPeng P7 AWD Performance

Front PMSM: 196 kW / 390 Nm; Rear PMSM: 120 kW / 265 Nm.

Combined: 316 kW, 655 Nm.

Fully variable torque distribution across all wheels, ensuring traction in all conditions.

📊 Which Setup is Best?

Dual IM: Lower efficiency, shorter range—less popular in China.

Dual PMSM: High efficiency but sometimes overkill; evolving toward mixed setups.

PMSM + IM: Optimal balance—high efficiency, strong performance, and good range.

A clear example: The new NIO ES8 replaced one induction motor with a PMSM and gained +60 km range instantly.

🏁 Conclusion

Dual-motor systems deliver better efficiency, performance, and regenerative braking, but also introduce more complexity in power coupling and control algorithms. The right motor pairing depends on the balance between cost, performance, and range.

With technology evolving rapidly, expect to see more mixed PMSM + IM setups dominating the market in the coming years.

Please explore our blog for the latest news and offers from the EV market.