Intelligent Battery Thermal Management System : The Core of Temperature Control in New Energy Vehicles

Winter range loss, overheating alarms during fast charging, and accelerated capacity degradation after long-term use—these are common concerns for EV owners, and most of them stem from uncontrolled battery temperature. The Battery Thermal Management System (BTMS) creates a “constant temperature shield” around the power battery. By keeping the battery within its optimal range of 25–35℃, it ensures both safety and performance, extending driving range and battery lifespan. Today, BTMS has become one of the key competitive advantages in new energy vehicles.

⚙️ Core Mechanism: “Full-Range Control + Dynamic Adjustment”

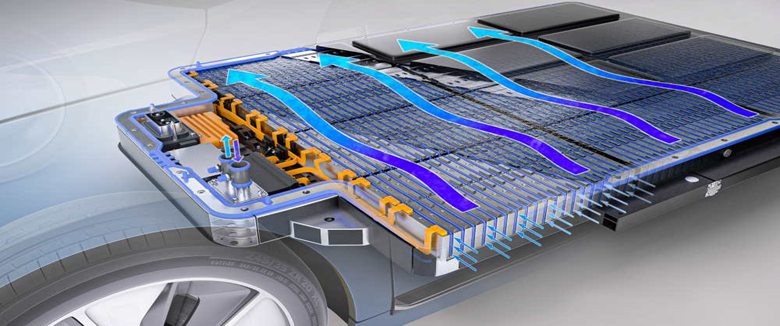

The smart BTMS integrates NTC temperature sensors (one sensor per 2–3 cells, accuracy ±1℃), liquid cooling pipelines, heating plates, fans, heat pump air conditioning, and the Battery Management System (BMS).

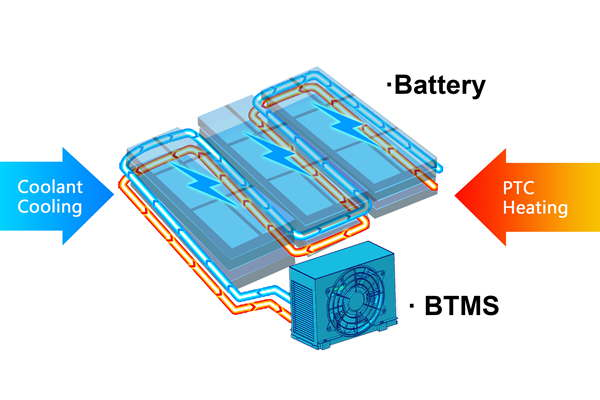

Low Temperatures (<20℃): When starting in winter, the BMS initiates heating. Below –10℃, PTC heating plates (3–6 kW) rapidly raise the temperature. Near 20℃, it switches to the heat pump, which saves up to 50% energy.

High Temperatures (>35℃): During fast charging or summer heat, the liquid cooling system activates. Coolant circulates around battery modules, carrying heat to the condenser, while fans accelerate airflow. This achieves a cooling rate of up to 5℃ per minute.

Temperature Balance: If temperature differences between cells exceed 5℃, the system fine-tunes local coolant flow to ensure uniformity.

Unlike traditional systems that only cool or heat, BTMS maintains precise constant temperature across all conditions.

🌡️ Beyond Traditional Cooling: All-Scenario Adaptation

Earlier EVs relied on passive fans or single heating methods. These could not handle diverse environments:

In winter, heating through the cabin AC consumed much energy and warmed slowly.

In summer, insufficient cooling often triggered power limits.

Smart BTMS solves this with scenario-based adaptation:

Cold Start in Winter: The system preheats the battery to 15℃ before allowing fast charging, preventing cold-temperature damage.

Hot Summer Driving (38℃): Liquid cooling + heat pump work together to cap battery temperature below 38℃, slowing aging.

Highway Cruising: The system predicts energy demand and pre-adjusts cooling power to prevent sudden spikes.

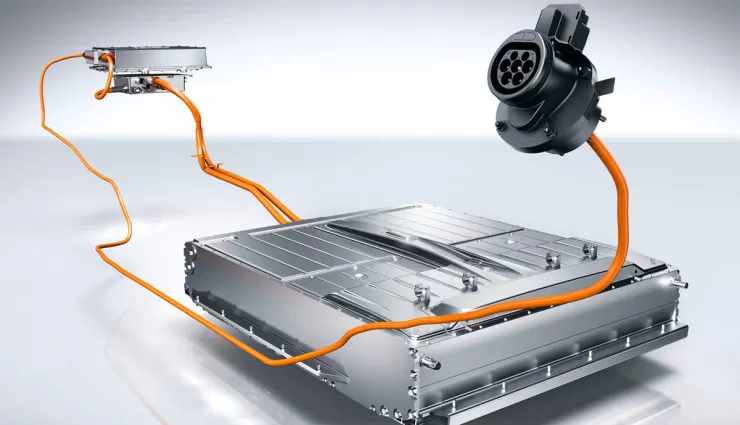

⚡ Fast Charging: The Critical Battlefield

Fast charging is the toughest challenge for temperature management.

Before charging, BTMS preheats the battery to 25℃ for maximum efficiency.

During charging, temperatures are checked every 10 seconds. If any area exceeds 38℃, charging power is reduced (e.g., from 120 kW to 80 kW) while targeted cooling is applied.

In the last 5 minutes of charging, cooling intensity is reduced to avoid overcooling.

In winter, users can set preheating appointments via a mobile app. The system warms the battery 30 minutes before departure, boosting range by 20–30% compared to non-preheated driving.

🧠 Long-Term Battery Health Maintenance

BTMS does more than just real-time control—it also manages long-term battery health:

Tracks every charge/discharge temperature curve to generate a battery health report.

Issues reminders if certain cells often overheat (“Check cell status”) or if long-term low-temperature use is detected (“Perform full charge-discharge to reactivate activity”).

At end-of-life (capacity <80%), it relaxes the temperature range to 20–40℃, sacrificing performance for longevity.

In extreme cases (collision or puncture), BTMS cuts off high voltage and activates thermal runaway suppression, injecting fire-retardant medium inside the pack.

🚗 Real-World Benefits: Range and Safety Boost

Data shows that cars equipped with BTMS deliver significant improvements:

At –10℃, range retention is about 80%, compared to only 60% in conventional systems.

Battery cycle life exceeds 1,200 cycles, versus 800 in older designs.

Risk of thermal runaway is reduced by up to 90%.

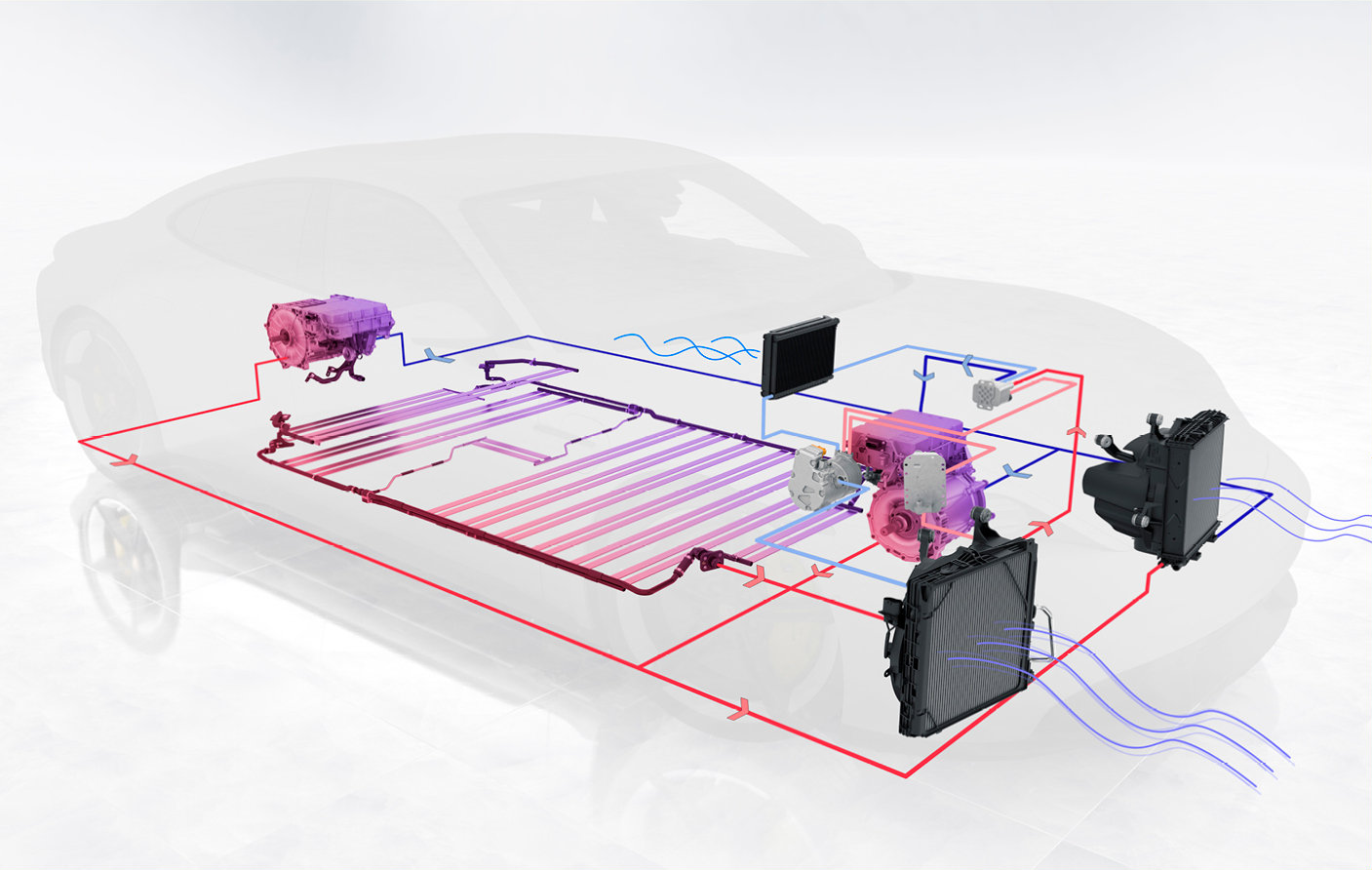

🔄 System Collaboration: Building an Energy Loop

BTMS does not work in isolation—it integrates with other systems:

With HVAC: In winter, cabin heating uses battery waste heat to save power; in summer, AC cooling reuses heat from battery dissipation.

With Smart Navigation: Predicts temperature changes along the route (e.g., “Entering mountain area in 50 km, temperature drops 5℃”) and adjusts cooling ahead of time.

With Charging Stations: Communicates battery’s current and target temperature to optimize charging voltage and current.

🏆 Conclusion: From Temperature Control to Energy Stewardship

Today, smart BTMS is a standard feature in most EVs.

Entry-level models (~$20,000) typically offer basic liquid cooling + heating.

Mid- to high-end models (~$40,000+) integrate heat pump + liquid cooling + zonal precision control.

It is no longer just a “temperature regulator,” but an energy steward that optimizes every kilowatt-hour. By prioritizing battery health and safety, BTMS represents the transition of EV technology from hardware competition to software-driven energy efficiency—making every unit of power deliver maximum value.

Please explore our blog for the latest news and offers from the EV market.