EV Tech Explained: What is the 800V High-Voltage Platform Architecture?

In the world of new energy vehicles (NEVs), the term “800V high-voltage platform” is frequently mentioned. It’s often seen as a benchmark of advanced EV technology—if a car doesn’t support 800V, some argue it’s not truly high-end. But what exactly is the 800V platform? Why is it quickly becoming the standard for premium models? In this post, we’ll break down the fundamentals, advantages, challenges, and market trends surrounding the 800V architecture.

Catalog

🔍 What is the 800V High-Voltage Platform?

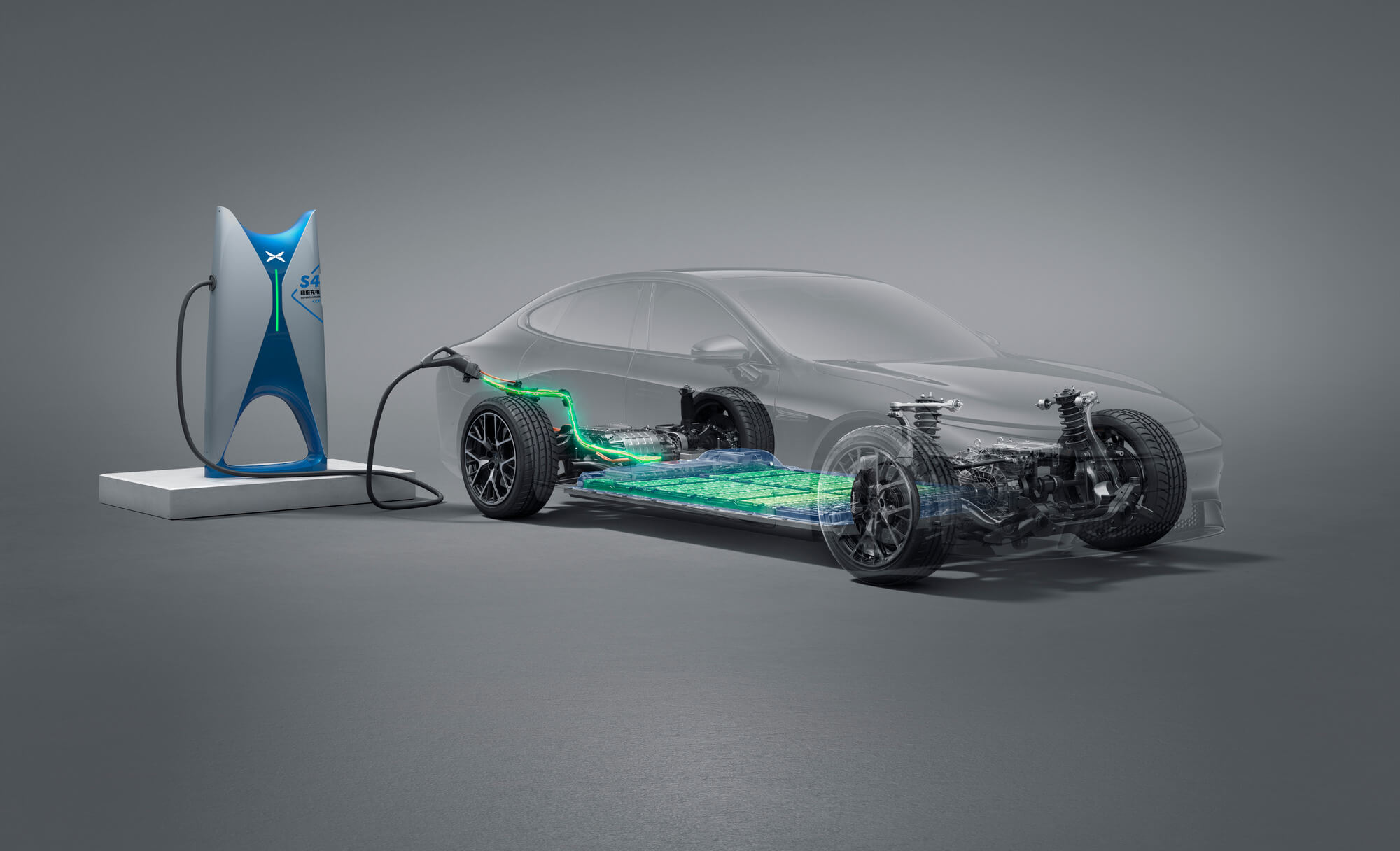

At a basic level, the 800V platform refers to a vehicle’s high-voltage electrical system—covering the battery pack, motor, inverter, and charging port—operating at approximately 800 volts. This represents a significant upgrade from the mainstream 400V systems seen in most EVs today.

However, it’s important to note:

The system doesn’t maintain a fixed 800V; the voltage typically ranges from around 550V to as high as 950V, depending on the battery’s charge state and configuration.

The term “800V” is more of a category describing systems that operate within this high-voltage range.

In short, an 800V platform allows the vehicle to maintain efficient high-voltage operation across a wide working range.

✅ Four Key Advantages of the 800V Platform

1. Faster Charging — Higher Voltage, More Power

Based on the power formula P=U×IP = U × IP=U×I, increasing voltage (U) at a constant current (I) leads to higher charging power.

With an 800V system connected to a 350kW ultra-fast charger, a vehicle can charge from 10% to 80% in just 10–15 minutes.

In comparison, 400V systems typically max out at around 150kW.

This enables EVs to recharge almost as fast as refueling a gasoline car—hugely appealing to users.

2. Lower Energy Loss — Improved Efficiency

Cutting the current in half reduces I²R transmission loss by 75%.

When paired with silicon carbide (SiC) components, overall system energy consumption drops by another 10–15%.

This leads to better range, improved thermal efficiency, and enhanced system reliability.

3. Enhanced Performance

Higher system voltage allows greater instantaneous power output, improving acceleration and hill-climbing capabilities.

Regenerative braking is also more effective, boosting energy recovery and driving dynamics.

4. Vehicle Weight Reduction & Component Optimization

Lower current enables the use of thinner, lighter cables and connectors, streamlining the vehicle’s wiring.

SiC inverters are more compact and require less cooling, further reducing vehicle weight.

⚠️ Challenges of the 800V Architecture

1. Higher Costs

800V components (SiC inverters, high-voltage batteries, specialized cabling) cost 20–30% more than 400V equivalents.

Many high-end parts must meet advanced certifications like ASIL D safety standards.

2. More Complex Thermal Management and BMS

Higher voltage results in greater thermal density, requiring more sophisticated cooling systems for batteries and inverters.

More battery cells mean more complex Battery Management Systems (BMS), voltage balancing, and monitoring.

3. Limited Charging Infrastructure

Globally, 800V-compatible fast chargers are rare (only ~1.5% in the U.S., ~3% in the EU).

While some 400V stations are compatible, they limit the performance of 800V systems.

4. Lack of Standardized Charging Protocols

Automakers and charging operators often use proprietary ultra-fast charging protocols, limiting interoperability.

Global compatibility across GB/T, CCS, and CHAdeMO at high voltages still needs work.

5. Stricter Vehicle Safety Requirements

Higher voltage requires improved insulation, arc protection, and spacing.

Risks such as high-voltage arcs and insulation failure must be mitigated through advanced design safeguards.

🚗 Industry Trends and Key Vehicle Examples

1. Leading Automakers Taking the Lead

Porsche’s Taycan (2019) was the first mass-production EV with an 800V system (up to 270kW charging).

VW Group’s PPE platform (Audi Q6 e-tron, Porsche Macan EV) and Hyundai’s E-GMP (Ioniq 5/6, Kia EV6) also adopt 800V.

Chinese brands like BYD (Seal, Song), XPeng (G9), and others such as Hongqi, Zeekr, and Li Auto are following suit.

2. Infrastructure Is Catching Up

Grid operators and charger companies are deploying 800V+/350kW fast-charging stations to support new-generation vehicles.

Governments are also updating road charging standards (EU NEVI plan, U.S. interstate fast-charging rollout, etc.).

3. Tech Improvements Lowering Costs

SiC production costs are expected to drop with increased scale.

Platforms like E-GMP and PPE help standardize components and streamline R&D and manufacturing.

4. Future Outlook: Solid-State Batteries

These batteries offer higher voltage capabilities and will pair well with 800V systems, boosting range, power, and safety.

🎯 800V: Mainstream Future or Premium Feature?

The 800V architecture is currently transitioning from a high-end niche to broader adoption:

Premium models (e.g., Porsche, BMW, Mercedes) are leading the charge.

Mid-range and mass-market vehicles (Hyundai, Kia, BYD) are quickly catching up.

By 2025–2030, 800V is expected to be standard in 30–50% of EVs globally.

📊 Summary: 800V vs 400V Comparison

| Attribute | 🔋 800V High-Voltage Platform | 🔌 400V Traditional System |

|---|---|---|

| Charging Speed | ⚡ Up to 350kW, 10–15 min to 80% | ⏱ Up to 150kW |

| Energy Efficiency | 🔋 Lower losses, 5–15% better range | 🔻 Higher I²R losses |

| Vehicle Weight | 🛻 Lighter wiring, compact components | ⚖️ Heavier wiring |

| Cost | 💰 Higher parts and system cost | ✅ Lower, mature manufacturing |

| Safety Design | 🛡 Stricter insulation and arc control | 🚧 Standard safety measures |

| Infrastructure | 🏗 Requires high-power charger rollout | 📡 Widely available and compatible |

🧠 Final Thoughts

The 800V platform represents a transformative shift in EV design—“high voltage, low current” delivers fast charging, better performance, and greater energy efficiency. While challenges remain, such as cost and infrastructure gaps, the trajectory is clear: this is a foundational technology for the next generation of EVs, especially those targeting the premium market or export growth.

Please explore our blog for the latest news and offers from the EV market.