Comprehensive Guide to Automotive Chassis Suspension Systems

As the core bridge connecting the vehicle body and the road, the chassis suspension system directly determines driving quality and safety performance. For new energy vehicles (NEVs), the suspension system also plays a crucial role in battery weight distribution and impact buffering during energy recovery. This article provides an in-depth analysis of suspension technology and upgrade strategies.

Catalog

1. Three Core Functions of the Suspension System

- Dynamic Stability Control

Through the synergy of geometric structure and mechanical design, the suspension system maintains optimal tire contact area, ensuring efficient power transfer during acceleration/braking and reducing body roll in corners. The low center of gravity from battery packs in NEVs can decrease body roll risk by 20%-35%.

Road Impact Absorption

A combination of springs and shock absorbers absorbs 80%-90% of road impact energy. Electric vehicles require optimized buffering to counteract the instantaneous drag force generated by the regenerative braking system.

Vehicle Posture Management

Smart suspension systems can dynamically adjust damping stiffness in real-time. For example, they prevent “nose lift” during hard acceleration and suppress “nose dive” during emergency braking, enhancing driving comfort and battery safety.

2. Analysis of Mainstream Suspension Technologies

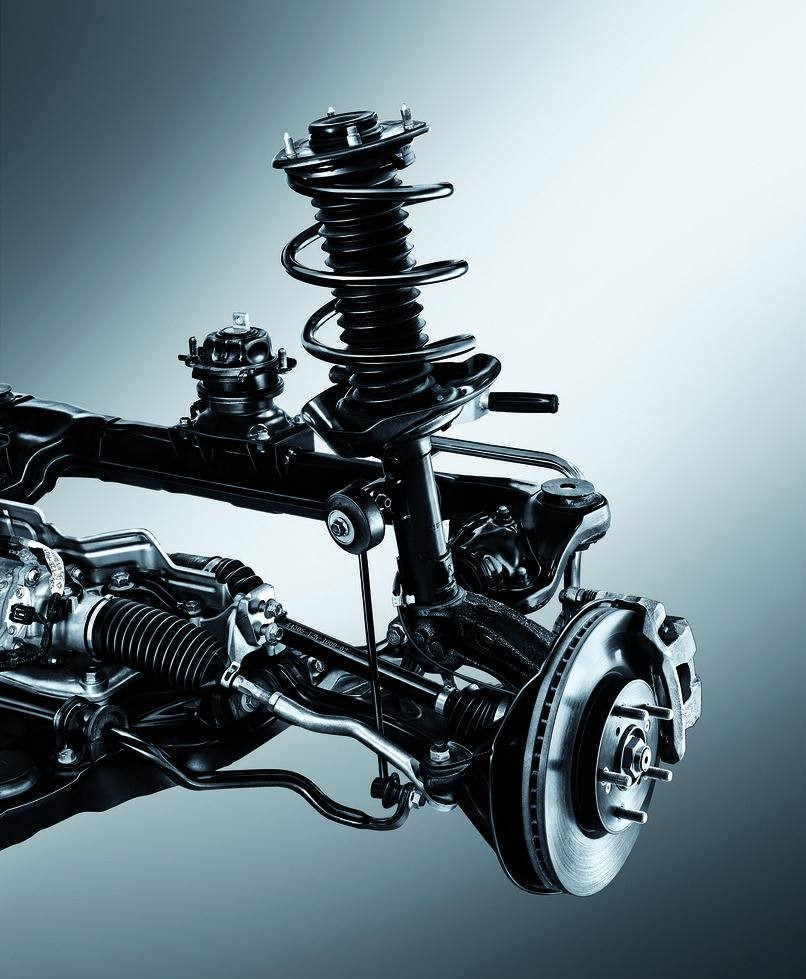

MacPherson Suspension

MacPherson suspension is one of the most widely used types, commonly found in passenger cars. It features a simple structure with coil springs, shock absorbers, and a triangular lower control arm. This design minimizes space occupation and reduces costs while providing adequate comfort for city driving. However, due to its structural characteristics, body roll is more pronounced during high-speed cornering or aggressive driving, limiting handling performance.

NEV Application: Standard front-wheel suspension for FWD models, suitable for front battery pack layouts, saving chassis space for electronic control modules.

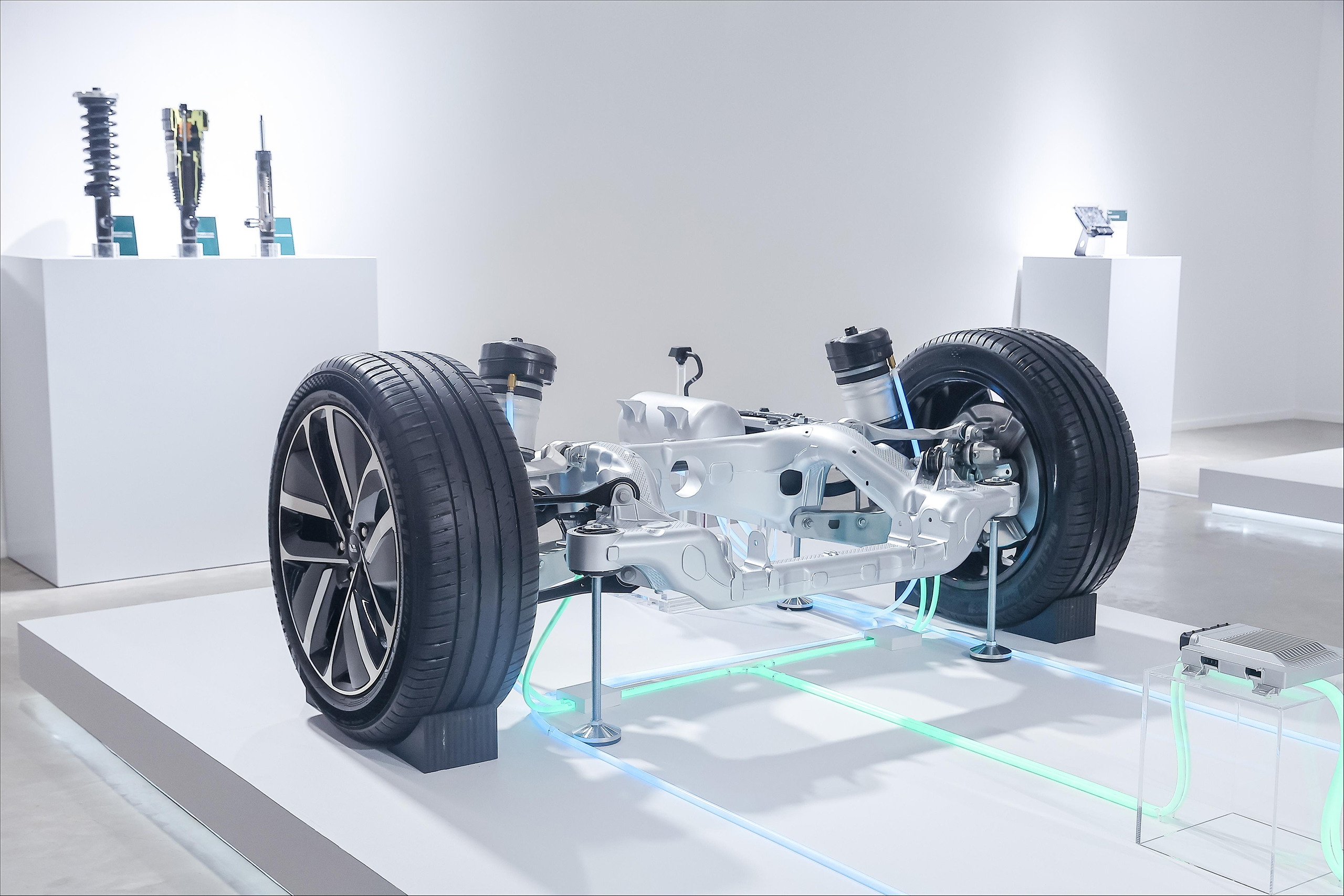

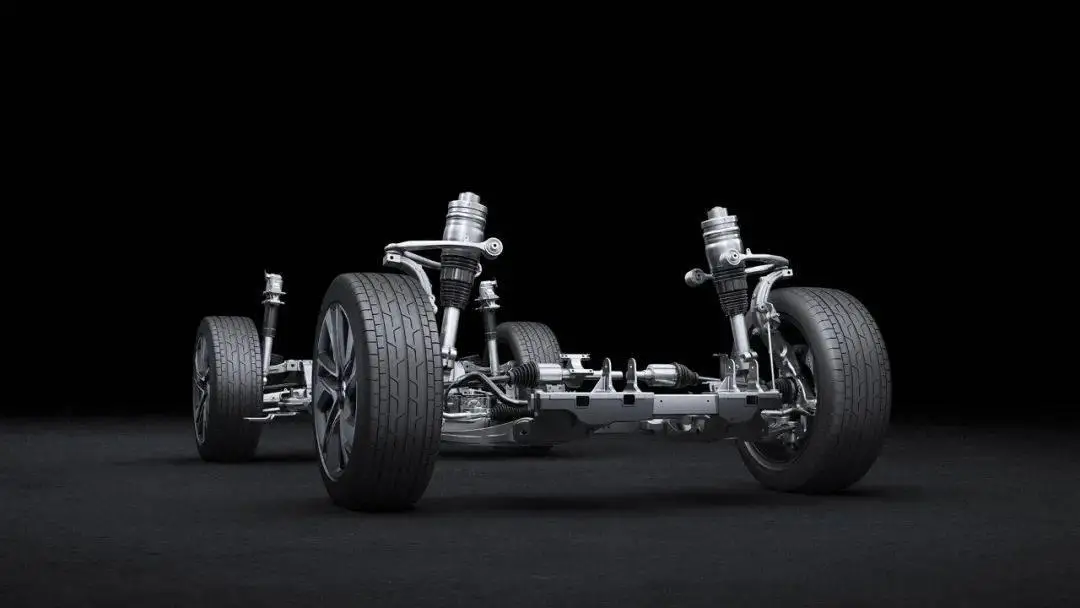

Multi-Link Suspension

Multi-link suspension consists of three or more control arms, precisely managing wheel movement to enhance both comfort and handling. It improves tire grip, reduces body roll during cornering, and provides a stable, precise driving experience. Additionally, it effectively filters out road bumps, creating a quiet and smooth ride. However, this system is complex, costly, and takes up more space.

Electrification Upgrades: Aluminum alloy control arms reduce weight by 30%; combined with active air suspension, it dynamically adjusts ground clearance to protect the battery pack.

Torsion Beam Non-Independent Suspension

Commonly found in small and compact cars, the torsion beam suspension connects both rear wheels via a single torsion beam. It is simple, cost-effective, and space-efficient. On smooth roads, it provides basic comfort, but when one wheel encounters a bump, vibrations are transmitted to the opposite wheel, reducing ride comfort. Handling performance is also inferior to independent suspensions in complex road conditions or aggressive driving.

Low-Cost Solution: Used in some mini EVs’ rear axles; reinforced with a lateral support beam to compensate for rigidity, with special attention needed to resonance matching between the battery pack and suspension.

3. Unique Suspension Design Considerations for NEVs

- Weight Distribution Optimization

The battery pack adds an extra 300-800kg load, requiring recalculation of suspension support strength. For example, the Tesla Model 3 adopts a front double-wishbone and rear multi-link combination to achieve an ideal 50:50 weight balance. - Energy Efficiency Optimization

Low rolling resistance tires and active suspension improve driving range by 3%-5%. The NIO ET7, equipped with CDC (Continuous Damping Control) shock absorbers, adjusts damping 500 times per second based on road conditions. - Enhanced Safety Protection

High-strength cast aluminum components reinforce battery tray mounting points, ensuring battery displacement stays within 3cm during collisions. The Li Auto L9’s chassis reinforcement beam withstands impact forces 2.5 times the national standard.

4. Suspension System Upgrades

High-Performance Shock Absorbers

Shock absorbers are critical to both comfort and handling. Upgrading to coilovers or air shocks enhances damping performance. Coilovers allow height and damping adjustment for different driving conditions, while air suspension adjusts stiffness via air pressure, balancing comfort and performance.

- Upgraded Springs

Factory springs may not meet all driving demands. Performance spring upgrades, such as short or progressive springs, improve suspension characteristics. Short springs lower ride height, reducing the center of gravity and enhancing cornering stability while giving the vehicle a sportier look. Progressive springs adjust stiffness based on load and driving conditions.

- Anti-Roll Bar Installation

An anti-roll bar (sway bar) reduces body roll in corners. Upgrading to a thicker or adjustable sway bar improves handling. It redistributes forces between the inner and outer wheels during turns, reducing roll and enhancing stability.

Exclusive EV Upgrade Packages

- Battery Guard-Integrated Sway Bar:Increases thickness to 8mm, enhancing lateral rigidity while protecting the battery pack.

- Smart Adjustable Suspension Kit:Allows drivers to select “Eco/Sport/Off-Road” modes via the central touchscreen, adjusting ground clearance between 80-200mm.

- Composite Suspension Arms:A mix of carbon fiber and aluminum alloy improves strength by 40% while reducing weight by 25%.

Upgrade Considerations

- Recalibration of the Regenerative Braking Systemafter modifications.

- Thermal Management Allowancefor air suspension-equipped vehicles.

- Regular Inspectionsfor stress cracks at battery tray and suspension mounting points.

5. Routine Maintenance & Fault Warning Signs

Periodic Inspection Checklist

- Every 5,000 km:Check for uneven tire wear (EVs’ higher torque may cause excessive inner tire wear).

- Every 10,000 km:Inspect shock absorber seals for leaks, as EVs’ instant torque can accelerate seal aging.

- Before and after rainy seasons:Examine aluminum components for electrochemical corrosion, especially in coastal areas.

Warning Signs of Suspension Issues

- Squeaking noise over speed bumps →Bushings worn beyond safety limits.

- Vehicle drifts to one side while driving straight →Suspension geometry misalignment exceeds 1.5°.

- Uneven ride height after charging →Air suspension pump or sensor malfunction.

6. Future Suspension Technology Trends

- By-Wire Active Suspension

Eliminates mechanical linkages, controlling actuators via electronic signals. Response speed improves to 5ms (current CDC systems operate at 50ms). Already featured in the Mercedes-Benz EQS flagship model. - Energy-Recovery Suspension Systems

ZF’s latest GenShock technology converts road vibrations into electrical energy, extending EV range by an estimated 8-15km per day. - Cloud-Based Suspension Tuning

Uses vehicle networking and big data to automatically download suspension settings based on real-time road conditions. The XPeng G9 already pre-adjusts suspension modes according to navigation routes.

Conclusion

For new energy vehicle brands, an advanced suspension system is not only a demonstration of technological prowess but also a key to unlocking international markets. Selecting the right suspension setup for different driving conditions and regions significantly enhances the driving experience of Chinese EVs. If you need tailored solutions, feel free to consult our team.

Please explore our blog for the latest news and offers from the EV market.